Technical Explanations

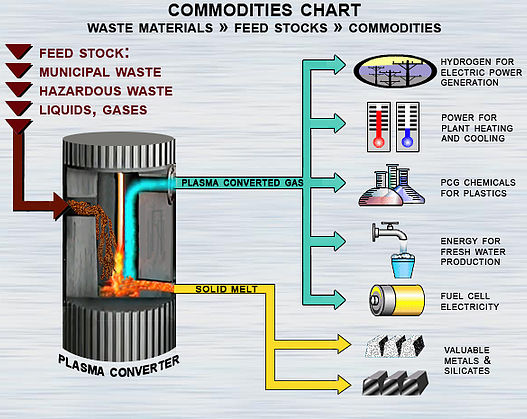

Plasma is simply a gas (air) that the Converter ionizes so it becomes an effective electrical conductor. It uses a lightning-like arc of intense electricity that it transfers to the waste material as radiant energy. The temperature of this plasma plume, contained in the vessel of the Converter, can be as high as 30,000 degrees Fahrenheit or three times hotter than the surface of the Sun. The effect of that extreme high energy is the excitation of the wastes’ molecular bonds; it causes them to break apart and disintegrate into their elemental molecular components.

The Plasma Converter is computer controlled.

It is a quiet and safe means of waste disposal.

The system operates at normal atmospheric pressure and is easy to understand.

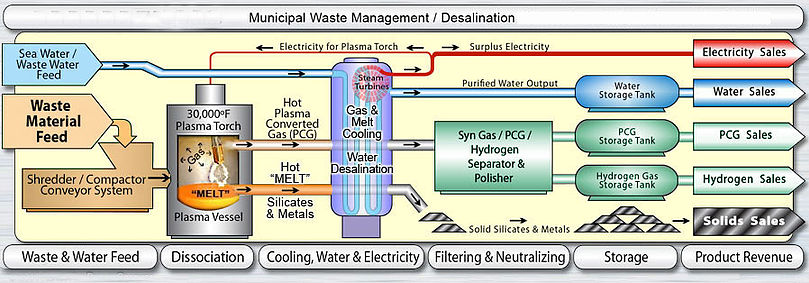

The basic Plasma Converter system consists of the following:

• Feed System

• Plasma Vessel

• Gas Polisher

• Computer Control Station

• Power Supply

Feed System

- The feed mechanism can simultaneously accommodate any proportion or combination of solid, liquid and gaseous feedstock.

- Solid wastes, depending upon their composition, can be pumped, screw fed, or ram fed into the plasma vessel. A shredder ahead of the feed system may be appropriate to achieve size reduction or object separation prior to direct system feed.

- Liquid wastes, including sludge, can be pumped directly into the PCS through the wall of the plasma vessel through a special in-feed nozzle.

- The liquid feed system is designed to also accommodate any entrained solids that may be present. Similarly, gaseous feedstock may also be introduced into the plasma vessel through a specially designed nozzle

Plasma Vessel:

The plasma vessel is a cylindrical two-part container made of stainless steel with an opening in the roof through which the plasma torch is inserted. The vessel is lined with insulation and refractory to allow both maximum retention of internal energy and to protect the stainless steel container from the intense heat inside the vessel. The plasma vessel is equipped with inspection ports (including a video camera so the operator can see real time images inside the vessel to assist in PCS operation), openings for introduction of feedstock, and an exit port for removal of excess molten material.

The PCS is equipped with a torch positional system that allows the operator to aim the torch at different points within the plasma vessel. This aspect of the PCS allows the operator to quickly and efficiently treat feedstock as they enter the vessel and move around inside the vessel to avoid any build-up of solidified melt that may occur on the vessel walls.

The plasma vessel is specially designed to ensure that no feedstock material is able to reach the exit port without first passing through the plasma energy field and undergoing complete molecular dissociation. In addition, the plasma vessel is maintained at a slight negative pressure to ensure that no gases can escape to atmosphere.

The most maintenance-intensive aspect of the PCS is the need to periodically replace electrodes, which occurs approximately every 300 to 500 hours of operation (typically). Electrode replacement can be accomplished in approximately 30 minutes thus ensuring minimum downtime of the PCS.

As well:

- The smaller Plasma Converter vessels are designed to remove molten material periodically through an automated tipping mechanism during which time the vessel may or may not remain in continuous operation.

- A design enhancement incorporated into the most recently constructed system is a continuous melt extraction feature which maintains the level of molten material in the plasma vessel at or below a preset limit without interrupting the operation of the system. This melt extraction system can be deployed with all sizes of Plasma Converters.

- Comparable plasma systems have been used extensively and successfully in the metallurgical industry for decades.Gas Treatment System/Gas Polisher:

The gas treatment system is comprised of six stages:

1. High temperature cyclone separator to remove particulates

2. Quench stage (with heat recovery, if desired)

3. Cartridge dust collector to remove particulates

4. Selective catalytic reduction to remove NOx

5. Packed column scrubber to remove acids and volatized metals

6. Final polishing1:High Temperature Cyclone Separator

The initial step of the gas treating process is a pre-quench in which the PCG is cooled from approximately 1000°C down to 650°C by direct water injection with a conventional spray dryer arrangement. The PCG then flows through a refractory lined pipe into a conventional, insulated cyclone fabricated with high temperature alloy and designed to operate at high temperatures. The purpose of the cyclone is to remove particulate matter, which is then collected and batch-fed back into the plasma vessel.2: Quench

PCG then flows to a spray dryer designed to rapidly reduce the gas temperature from approximately 650°C down to 120°C. This temperature reduction is important: it ensures that dioxins and furans, troublesome by-products of incineration, do not form. In order for dioxins and furans to form, the gas would need to remain in a specific temperature zone (e.g., 190°C to 330°C) over time – conditions which are precluded by the quench.3: Cartridge Dust Collector

PCG then flows to a commercial pulsejet cartridge dust collector with high-temperature cartridges and heating elements. This prevents condensation. This unit is capable of automatically “blowing back” solids; these are collected and batch-fed back into the plasma vessel.4:Selective Catalytic Reduction (SCR)

Upon exiting the dust collector, the PCG is reheated to approximately 310°C for selective catalytic reduction of NOx in a standard unit designed for this application. Hydrogen present in the PCG reacts with NOx to form atmospheric nitrogen and water. During periods where there is no hydrogen in the PCG (e.g. during start-up, when processing materials that do not contain carbon), urea is added to reduce the NOx.5:Packed Column Scrubber

Upon exiting the SCR, PCG undergoes a final quench with direct water injection to reduce the temperature below 50°C. This prepares the PCG for acid gas removal, which is accomplished in a standard horizontal packed column scrubber. Inorganic species dissolve into the scrubbing liquid as common ions such as chloride, fluoride, sulphate, phosphate, sodium and calcium. To manage the build-up of salts, the scrubbing solution is removed and replenished with fresh water. Typically, the wastewater requires no further treatment prior to discharge to sewer unless there has been an exceptional concentration of heavy metals entering the system as feedstock.6:Final Polishing

A standard variable speed fan at the exit of the gas treatment train pulls PCG through the entire system